A detailed comparison of the features and applications of industrial PCs for your specific requirements

Embedded Industrial PCs, 19″ Industrial server and more: The right hardware for demanding industrial applications

Industrial applications often require specialized hardware solutions to meet demanding requirements. In this blog post, we will take a closer look at the differences between Embedded Industrial PCs, 19″ Industrial PCs, Embedded Substation PCs and 19″ Substation PCs. Each of these device categories offers unique features and are suitable for specific applications. In addition to the obvious differences, individual customer requirements also play a role. For example, there are customers who may not require specific certifications such as IEC compliance, but who work in electromagnetically demanding environments, such as near large electric motors or radio equipment. In such cases, the use of industrial PCs that meet IEC standards, while not mandatory, can be useful to ensure reliable performance.

Versatile industrial PCs for powerful applications in different environments

Embedded Industrial PC

An embedded industrial PC is designed for industrial applications and offers high computing power for applications such as artificial intelligence, machine learning and control systems. These PCs usually come with certifications such as CE/FCC and can cover an operating temperature range from -20°C to +70°C, depending on the model. Depending on requirements, they can be fanless or equipped with a fan. The power supply is flexible around 24V, from 9/12V to 24/36/48V. Embedded industrial PCs are often mounted on DIN rails or on the wall.

Quick response to critical events: The role of industrial computers in crisis and alarm management

The compact embedded industrial computers, for example, provide a reliable basic module in the field of crisis and alarm management to quickly respond to critical events and initiate appropriate actions.

The industrial computer is connected to various sensors and alarm devices that continuously monitor information, such as fire, smoke, gas leaks or intrusion. These sensors send immediate warning signals to the industrial computer when a critical event is detected.

The computer analyzes the incoming alarms and runs predefined scenarios to notify personnel and coordinate appropriate responses. For example, depending on the type of alarm, the computer can automatically trigger an evacuation, notify emergency contacts, or activate safety protocols.

19″ Industrial PC

19″ Industrial PC are designed for use in racks. Equipped with certifications such as CE and partly FCC, these PCs are suitable for demanding industrial applications. They usually offer an operating temperature range of 0°C to 50°C and are equipped with a fan. Exceptions here are some 1U models, which are fanless. The power supply can be flexible and ranges from 100-240V AC to 12V/24V/-48V DC. Depending on the requirements, the units can also offer redundant power supply options. 19″ industrial PCs are suitable for applications such as artificial intelligence, machine learning, control systems and other custom use cases with high computing power requirements.

Quality improvement and error detection: the role of 19-inch industrial computers in electronic manufacturing processes

In electronic manufacturing plants, a 19-inch industrial computer is used to automate the control and monitoring of the production process. It collects data from sensors, controls machines, and allows personnel to monitor the process in real time. The industrial computer improves efficiency, quality and error detection in manufacturing.

The application areas of 19″ industrial PCs overlap to a large extent with those of embedded industrial PCs. The use of a 19″ industrial PC is mostly based on the equipment of the plant. Customers who choose a 19″ model already have the appropriate cabinet installed in their application.

Are you looking for an industrial PC that meets your requirements? Would you like to know what to look for when making your selection? In our current blog post you will find all the important information about the selection criteria and requirements for industrial PCs.

Industrial PCs for Substations

Embedded Substation PCs are specifically designed for use in substations where they must withstand challenging EMC environments. These PCs meet certifications such as IEC 61850 -3 and IEEE 1613, as well as CE/FCC/UL/CB where applicable. With an operating temperature range of -40°C to +70°C, they offer rugged performance even in extreme conditions. The fanless design with no moving parts ensures reliable and long-lasting operation. Power is supplied via a redundant input of 20-54V DC. Embedded Substation PCs are often DIN rail or wall mounted and are used in substations as well as in industrial applications with medium computing power requirements

Efficient Control and Monitoring: The Role of Embedded Substation PCs in Electrical Substations

Embedded Substation PCs are used in electrical substations or substations to provide control, monitoring and analysis of the electrical infrastructure. The Embedded Substation PC collects data from various devices in the substation, such as transformers and switchgear, and provides real-time information on current flow, voltage and device utilization. This allows operators to monitor network health, detect faults and schedule maintenance. In addition, the Embedded Substation PC serves as an interface to a higher-level control system to optimize substation operation and ensure efficient power distribution. Overall, the Embedded Substation PC improves the reliability, efficiency and safety of the electrical network.

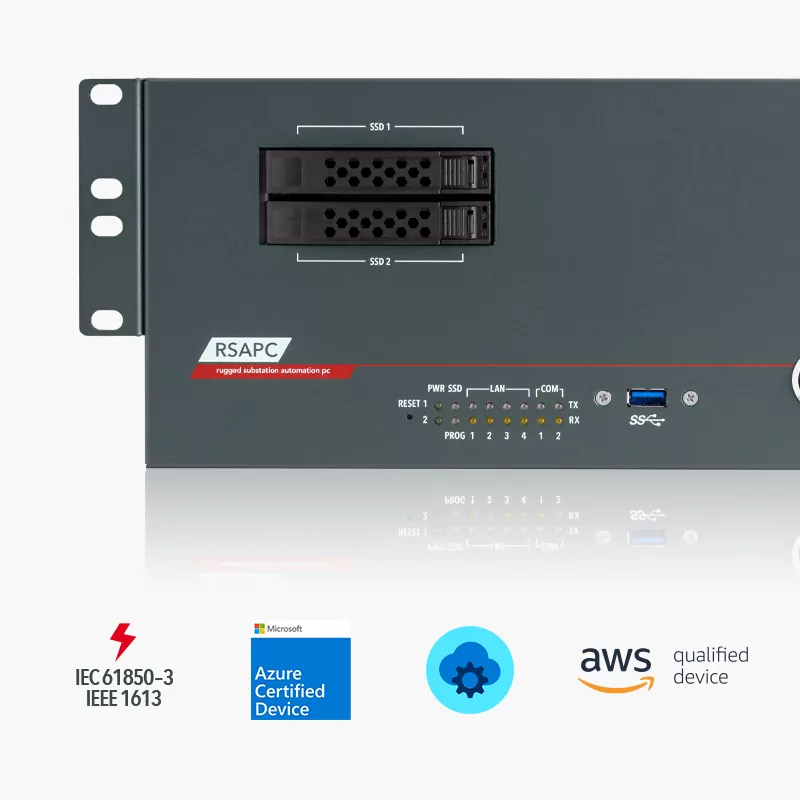

19“ Substation PC

The 19″ Substation PC offers similar features as the Embedded Substation PC and is also designed for use in substations. It complies with IEC 61850 and IEEE 1613 certifications and possibly other certifications such as CE/FCC/UL/CB. With an extended operating temperature range of -40°C to +75°C and an electrical heating system, the 19″ Substation PC offers reliable performance even under extreme conditions. This PC is also fanless and has no moving parts. Power options include two slots that can be mixed and redundant, and range from 16.6-160V DC to 100-240V DC (HVDC) or 100-240V AC. The 19″ Substation PC is suitable for both substation and industrial applications with difficult EMC environments and high computing power requirements. The ability to use these rugged PCs can help companies operating in electromagnetically challenging environments ensure reliable performance.

Innovative technology for advanced substation automation

The 19″ Substation PC, for example the Welotec RSAPC is a solution for fully software-defined substation automation. It allows easy and flexible implementation of IEC 61850 in Process Bus and Station Bus. Application virtualization provides extensible functionality and the design ensures state-of-the-art cybersecurity. The RSAPC replaces traditional copper cabling with fiber and enables centralized or virtualized use of IEDs on a server. Efficient and advanced substation automation is thereby enabled.

Want to learn more about this application of RSAPC? Explore our joint case study with Locamation, in which we introduce you to the use of RSAPC in a software-defined substation!

Comparison table: Comparison of PC types

| Difference | Embedded Industrie PC | 19" Industrie PC | Embedded Substation PC | 19" Substation PC |

|---|---|---|---|---|

| Certifications | CE/FCC, partly UL | CE, partially FCC | IEC 61850 + IEEE 1613 (+CE/FCC/UL/CB) | IEC 61850 + IEEE 1613 (+CE/FCC/UL/CB) |

| Operating temperature range | Depends on the model, min. -20 to +60° | 0-50°C | -40 to +70 °C | -40 to +75 °C, electric heating system |

| Fanless | Fanless / with fan | with fan (exception 1U) | Fanless (no moving parts) | Fanless (no moving parts) |

| Power supply | variable around 24V (9/12V to 24/36/48V) | variable: 100-240AC 12V/24V/-48V DC 100-240V DC Redundant or Single | Redundant input 20-54V DC | 2x slots, mixable, redundant: 16.6 - 160V DC 100-240V DC (HVDC) 100-240V AC |

| Mounting | DIN rail, wall mounting | 19" rack | DIN rail, wall mounting | 19" rack |

| Applications | Industrial applications: AI, MI, controls, various custom use cases and medium to high compute power requirements | Industrial applications: AI, MI, controls, various custom use cases andhigh computing power requirements. | Substations, Industrial applications with difficult EMC environment and medium computing power requirements | Substations, Industrial applications with difficult EMC environment and high computing power requirements |

Feel free to contact us

Individual solutions are our passion. Are you looking for the optimal industrial PC for your application? We look forward to hearing from you so that we can provide you with the best possible advice. Use our contact form now.